Article Source. Author: Leon Louw, Why Africa, https://www.whyafrica.co.za/captains-of-mining-at-a-crossroad/” CAPTAIN OF MINING AT A CROSSROADS

Captains of mining at a crossroad

Captains of mining at a crossroad

Amid global calls for decarbonisation and net zero carbon emissions, mining’s decision makers, under increasing pressure to reform, can do so easier than they may think.

By Leon Louw

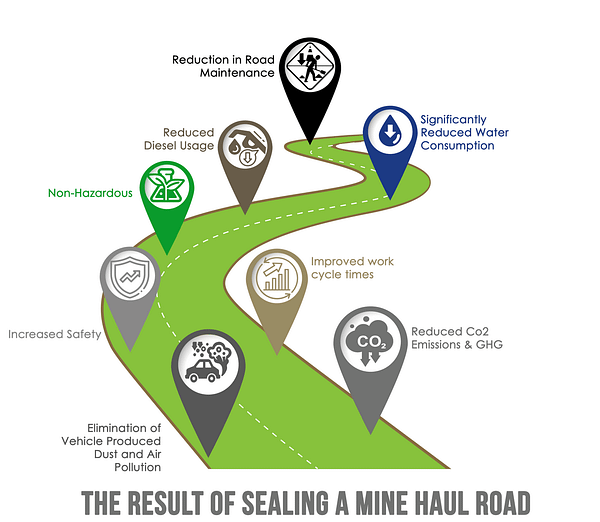

The mining industry is at a crossroad. The road to the right is a sustainable one that provides many benefits and leads to a new beginning. The road doesn’t require continues maintenance and there are no billowing clouds of dust.

The road to the left, on the other hand, is eroded, corrugated and dusty with poor visibility. It consumes millions of litres of water every month and several unfortunate safety incidents have taken place along the route in the past.

It has been used repeatedly for decades. Despite setting aside a substantial portion of unprotected capital for the road’s construction, it still requires constant maintenance to ensure drivability. Daily maintenance drains operational expenditure and contributes to the mine’s liability and risk matrix in terms of health and safety. If you are at this crossroad, which route will you choose?

Will you choose The Right Haul Road to Route 2030? The road of decarbonisation and net zero emissions? Or will you habitually “keep the status quo” and without thinking, force your ADT into second gear, turn left, and labour the yellow metal all the way down to Doomed Posterity.

Route 2030 leads to a cleaner, greener, and unpolluted Nirvana with blue skies. Sounds easy. Changing gears more often can’t be that difficult, right? Well, there’s a hitch. It is not only the driver’s responsibility to deliver his payload to Net Zero Nirvana. If it was, Net Zero Nirvana will remain only blue sky, a figment of the imagination of those drivers who met for COP 26 in icy Scotland last year and decided that the world will take the road less travelled.

When the industry leaders who met for COP 26 made that call, they placed a heavy burden on the shoulders of their fellow human beings, and even more so on the world economy, the extractive industries, and especially mining.

The decision to take the right road, will have earthshattering and unintended consequences for the mining industry. It calls for stepping out of current comfort zones and out-of-the-box thinking. Most of all, it requires doing better. If implemented, the unintended consequences are overwhelmingly positive.

To be sustainable will require the entire mining industry to change habits. To realise that “status quo” is not what we should aim for, and to change the way we think and operate.

Sustainability a blessing, not a curse

Sustainability a blessing, not a curse

Achieving sustainability in mining is, according to Sharon Schoutens, managing director at Soil Solutions, a lot easier that what we think it is. What’s more, effective solutions can be implemented now, which would, at the same time, reduce current operational costs. “There is no justification to delay the change, positive change can happen right now,” says Schoutens. Thus, that rocky first section of Route 2030, is not so daunting after all.

Soil Solutions turned right onto Route 2030 way before ESG and sustainability reporting, and climate change was top priority for the mining industry.

The company started its journey in 2004 when they identified the need for more cost-effective and sustainable solutions that would allow mining companies to reduce their environmental impact, while still increasing efficiency and realising cost reductions. This resulted in the development of the company’s advanced Engineered Base Stabiliser.

“Our passion for the environment and to make a difference are our key driving forces,” says Schoutens. During the harsh Covid-19 lockdowns, the company spent a lot of time thinking about how they could increase their positive impact and share that knowledge with their clients.

“The status quo was not good enough and it was time to challenge it. As a result, dIAta was born to merge our value-engineered solutions with data that will allow our clients across varied sectors to play a vital and quantifiable role in the fight against climate change, and in the process, improving the world for future generations,” says Schoutens.

There is increasing pressure on mining companies to reduce their environmental impact. Reducing carbon emissions, however, is not always as easy as it sounds. Plant and equipment on site have traditionally been driven by fossil fuels, and to suddenly cut emissions by replacing these old-timers with electric or hybrid versions, for example, is pure pie in the sky. The costs will be enormous, and it will take time to replace a whole fleet of equipment and vehicles.

But stepping up and making the change, doesn’t necessarily have to entail large ticket items or cost intensive capital decisions. Although the pressure to do something can be intimidating, Schoutens advises that operations should rather focus on small changes. “Small changes can have big effects,” she says.

Review entrenched practices

Stop procrastinating

The first step to effective change, is change itself. Mining operations need to review those traditional, entrenched practices that have become part of the company’s culture. Although change is always a challenge, real change is executed through numerous actions put into motion in a holistic and strategic way so that the outcome will have an exponential effect.

Easy to say but what can a mid-level mine manager actually do? The answer is, surprisingly, A LOT. “Start with the easy and obvious,” explains Schoutens. “For example, replace outdated habits with more advanced and sustainable practices.”

A good example of outdated, un-sustainable habits is the way that mining operations design, construct and maintain their road network.

The road network of any mine is a major component of its initial capital outlay. Nonetheless, most mining operations do not protect this investment and within the first-year road maintenance becomes a constant drain on operational expenditure. Moreover, it has a large negative environmental impact, even if it does not have to be.

By tackling the under-performance of haul roads, a miner immediately mitigates at least some of the harshest environmental impacts, and these are the small changes Schoutens refers to above. According to R.J. Thompson in Mining Roads: Mine haul road design construction and maintenance management the mine haul road network is a critical and vital component of the production process.

Road networks are critical

“As such, under-performance of a haul road will impact immediately on mine productivity and costs. Operational safety, work cycle efficiency, and equipment longevity are all dependent on well-designed, constructed and maintained haul roads.

The Road network of a mining operation is an asset and should, in conjunction with the haul trucks using the road, be designed to deliver a specific level of performance and its routine maintenance managed accordingly. A well-built and maintained haul road will enable haul trucks to operate safely and efficiently. Poor roads pose safety problems for not just haul trucks, but also all road-users. A well-designed, constructed and maintained haul road has significant advantages for a mining operation, not the least of which are:

- Increased safety and improved driving conditions and reduced liability ;

- Reduced road maintenance costs, less spillage, No Dust ,

- Reduced Vehicle Maintenance & Tyre wear

- Reduced operating costs,

- improved work cycle times =higher productivity and lower cost per ton ;

Reducing dust not such a small change

STOP. RE-THINK. DO BETTER.

According to Schoutens, the dust generated from mine haul traffic contributes to air pollution, generates large amounts of carbon emissions, and creates safety and liability issues. “All of these factors can be easily eliminated with a more sustainable approach to road construction and maintenance,” says Schoutens.

“The upgrade and sealing of a gravel mine haul road will eliminate the dust, protect the road surface from erosion and material loss, and allow for a safer and healthier workplace. Moreover, it will reduce the need for constant maintenance, which will decrease CO2 emissions as a result of the elimination of constant operation of graders, rollers, and water tankers. In addition, billions of litres of water will be saved,” she adds.

Soil Solutions provides a highly durable and effective long-term solution that is achieved with the integration of a technologically advanced material sealer and stabiliser that is applied only once annually. Typical dust control methods often require multiple application in one week. One small change and action that results in a massive positive effect.

Not only do these measures tick all the boxes of sustainability and cutting carbon emissions, and massive reduction in water use, but it also leads to reduced operational costs. In the end it is a “ no brainer” .

“There are also many peripherals or additional benefits that stem from simple actions like sealing pavement surfaces, for example. This inevitably results in reduced maintenance, operational costs, water use and tyre wear, while it increases safety, sustainability and work cycle efficiency and decreases liabilities,” says Schoutens.

The benefit of making this change outweighs the costs significantly.

A mine that upgrades and seals a 20 km road network will see substantial water savings, reduced diesel burn and a marked reduction in carbon emissions.

Incorporating data management will allow mines to load this CO2 data onto specific platforms for carbon credits (Soil Solutions’ dAIta sector can set this system up for clients). The data can also be included in the required annual sustainability reporting.

Incorporating data management will allow mines to load this CO2 data onto specific platforms for carbon credits (Soil Solutions’ dAIta sector can set this system up for clients). The data can also be included in the required annual sustainability reporting.

Small changes can produce big effects and even more important results. The results are a win-win scenario for the mine’s bottom line, and for the environment.

Most mining companies are sitting at this crossroads wondering what they can do, and how to do it. The answer is quite simple: small steps to prevent the status quo, but most of all, to do better!

A mine that upgrades and seals a 20 km road network will see substantial water savings, reduced diesel burn and a marked reduction in carbon emissions.

Water savings of 1.4 million litres per day

- 2 x 70,000 litre tankers watering 10 times per day

- 140,000 litres x 10 = 1.4 million litres of water per day

- 511,000,000 litres of water per year (511 million Litres of water per year)

Reduced Diesel

Fleet of 20 x CAT 789 Haul Trucks – improved fuel efficiency of 7.95 litres per hour (5%) per vehicle (159 litres per hour) (3,180 litres per day) (1,160,700 litres per year)

Reduced CO2

Based on the above fleet of 20 x CAT 789 Haul Trucks this would be a reduction in CO2 of 3,052,641 kg (3 million kg)